Marchmont House - The Candelabra

FRD has worked with Marchmont House on many projects including lanterns, fireplace fenders, exterior lights, fire backs and most recently a pair of replica 18th century ormolu candelabra originally designed by the neo-classical designer James “Athenian” Stuart. The two replicas stand alongside two originals on Robert Adam Lonsdale four carved gilt plinths in the saloon of Marchmont House.

There are six pairs of candelabra known to exist. One pair was originally displayed in The Painted Room at Spencer House, they were discovered at Carlton Towers in Yorkshire in the early 1990s. The original Spencer House pair is now at Althorp House in Northamptonshire. Another pair is in the collection of the Victoria & Albert Museum.

Spencer House, London

built between 1756 and 1766, was not just a family home and a venue for entertaining; it was also a private art gallery where the Spencer family could show off some of the most prized objects from their collection.

Today, Spencer House continues this tradition, containing an impressive assembly of paintings, furniture and other decorative objects carefully chosen to reflect the tastes of Lord and Lady Spencer and their contemporaries in the second half of the eighteenth century.

Among the pieces on display are several objects original to the house, commissioned by the Spencers to decorate their new London home. The current collection has been greatly enhanced through many generous loans from both private lenders and national museums including the Victoria & Albert Museum, Tate, Royal Collection Trust and Leeds Museums and Galleries.

“Stuart’s ormolu candelabra has long been recognised as one of the earliest expressions of neoclassicism in English design.”

The candelabra features a combination of baroque and classical elements and recalls the “compositions” of Sir William Chambers, drawn in Rome in 1750s. The foot of the vase, with its twisted, fluted and guilloche moulding, is probably taken from a baroque original while the tripod legs are also of baroque form. The high quality of the vase along with the carefully contrasted overlaid elements and use of gilt and matte surfaces point to Diedrich Nicolaus Anderson, a major ormolu manufacturer, as the maker.

On 8th July 2010 Christie’s Auction House held a sale of items from Spencer House, St James Place, London. Lot 1003 was a pair of George II ormolu three-light candelabra, almost certainly designed by James “Athenian” Stuart and probably made by Diederich Nicolaus Anderson, Circa 1758-65.

The Christie’s pair of candelabra were bought and taken to USA to sell on by the new owner. However, the price they were hoping to achieve was never realised and they did not sell.

James “Athenian” Stuart

is widely recognised for his central role in pioneering Neoclassicism, developing his influential career across various fields of interior decoration, sculpture, furnishing, metalwork and architecture.

Born in London in 1713, Stuart showed talent as an artist even as a child and was apprenticed to a fan painter. In 1742 he moved to Italy to improve his artistic skills. While there, Stuart worked as a painter and guide to antiquities while studying art and architecture and also learning Italian, Latin and Greek.

In 1751 Stuart visited Greece with Nicholas Revett to measure and record antiquities. The creation of the ‘Greek Style’ and its impact on British Design in the late 18th century is largely due to Stuart and Revett’s landmark publication ‘Antiquities of Athens’. The book was the first accurate record of Classical Greek architecture and served as a principal source book for architects and designers well into the 19th century.

Stuart’s furniture and metalware designs were eclectic in design, fusing Baroque forms with elements taken from early French and Neoclassicism. They also included direct copies of Greek and Roman ornament and furniture types.

The Christie’s Spencer House sale coincided with the restoration of Marchmont House. Oliver Burge was on a quest to find a pair of candelabra to display in the saloon at Marchmont House. Through the London silver dealer Koopman Rare Art, Oliver found another original pair. Koopman Rare Art is one of the world’s leading dealers specialising in antique silver, gold boxes, jewellery and objets de vertu. Oliver was keen to ensure that the candelabra he purchased matched the ones sold at Christies, and the ones in the V&A Museum, so he arranged for all six candelabra to be inspected by Francis.

Oliver then commissioned Francis and the team at FRD Designers & Makers to produce a second pair to replicate his originals. His vision; to display the set of four in the saloon at Marchmont House.

Ormolu

is a gold-coloured alloy of copper, zinc, and tin used in decorating furniture and making ornaments. The term originally referred to a process in which powdered gold was mixed with mercury and used to gild metal, a technique that was banned in the 19th century on account of its toxicity from the mercury released in to the atmosphere during the heating process.

A new safer modern technique was needed to replicate the process. FRD approached a company who specialised in electroplated gold, carrying out numerous tests to ensure the colour matched perfectly with the original ornaments.

The pair of candelabras acquired by Marchmont slightly differed from the other examples FRD inspected. The Marchmont pair had a marble base rather than the cast ormolu tripod. FRD were instructed was to replicate these elements on the contemporary replicas as well as the Marchmont pair.

It was noted that the V&A examples had been drilled for wiring and the top plate on the radiused triangular base appeared to be brass plate rather than the expected cast bronze. Other variances were an ormolu hemispherical detail to the base and top of the urn body and a spiral, fluted arm to the central candleholder.

A further observation on the Marchmont pair was that the nozzles (the component the candles fitted in to) were of a later date and produced in a technique not available to 18th century makers. These were replaced with beaded edge nozzles of the period.

The component parts of the Marchmont House candelabara

The project began with disassembling one of the original candelabras to identify how each component was made and plan the process for its replication.

Tests were carried out on the internal unseen parts to establish the safety of using silicone to create an impression of original components. The options on silicone were restricted by the need for no mould shrinkage.

Where appropriate silicone moulds were used on original component. Where this was not possible parts were drawn on CAD software and printed as 3D forms, these were used for the balance of the 26 moulds required to move to the next stage.

The wax “masters” were then made by pouring molten wax into the silicone. At this stage the lost wax casting technique aligned with how the original maker would have been working. The waxes were perfected using scalpels and chasing tools and additional “channels” added to perfect the flow of molten bronze around the shape. Where required further silicone moulds were made around the perfected shapes, in some cases smaller components were gathered and joined together on a wax shaft to be cast in multiples.

The completed waxes were then encapsulated in a modern version of a plaster mould, known as an “investment”. These were then fired in a kiln in two stages, firstly to melt the wax and carefully dry the mould, then taken to a higher temperature to burn out any remaining wax.

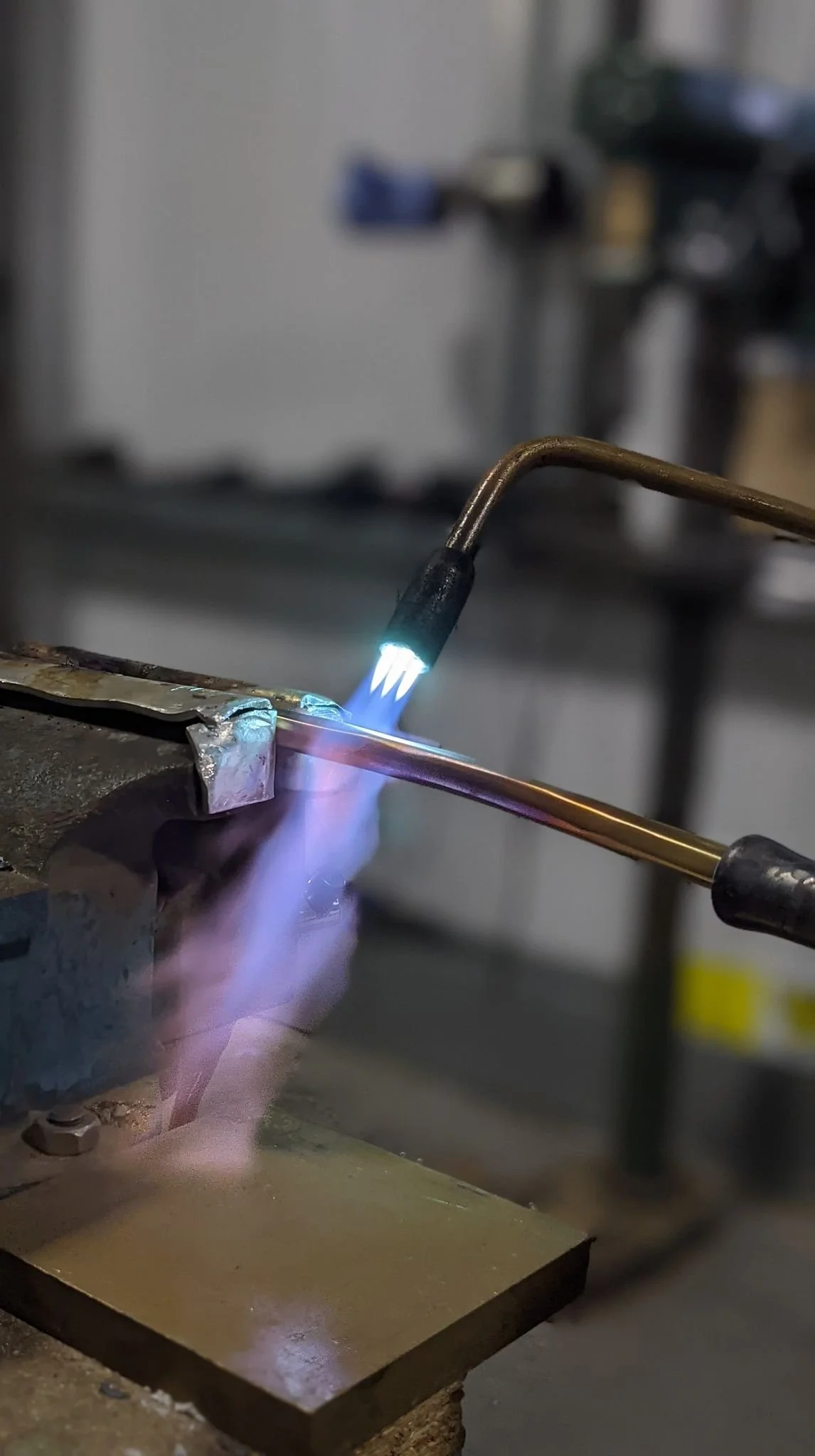

The bronze was melted from ingots in a propane furnace. The bronze heated to around 1100 degrees centigrade in a crucible. The crucible was lifted from the furnace and the molten metal poured into the investment mould. We used a vacuum chamber to contain the moulds to ensure the bronze was “pulled” into the small detailed areas. After cooling, the investment was broken away from the bronze form and the finishing process began.

The castings seldom come out of the mould without the need for filing, grinding and polishing. This is known as fettling. Any surface imperfections need removing as well as dressing out areas where additional elements were attached to ensure the metal flowed where needed. This is a lengthy, highly skilled operation. It is normal for there to be a high failure rate, the failed pieces being remelted for further pourings.

With the fettling complete the castings required machining, drilling and threading in order for all the pieces to fit together.

The candelabra components ready to be re-assembled

We trial assembled the candelabras prior to a final clean and polish of the components.

The original pair of candelabras were finished by painting the surface with a mixture of mercury and gold, the mercury was burnt off leaving the gold attached to the surface of the bronze. This process has long been redundant due to the extreme danger. The challenge was to reproduce this finish with electroplated gold. We approached several companies to assist, carrying out tests on spare bronze castings. We selected the closest colour match to the gilding on the original.

The electro-gilded sets of castings were then reassembled and the candelabras completed.

Using a combination of traditional and highly contemporary metal working techniques, our incredibly skilled team of designers, metal workers and finishers were able to reproduce exceptionally intricate metal ornaments, difficult to differentiate from the stunning original pair made over 250 years ago.

Acknowledgments: We are very grateful to Mr Oliver Burge of Marchmont Farms Ltd for the commission and encouragement.